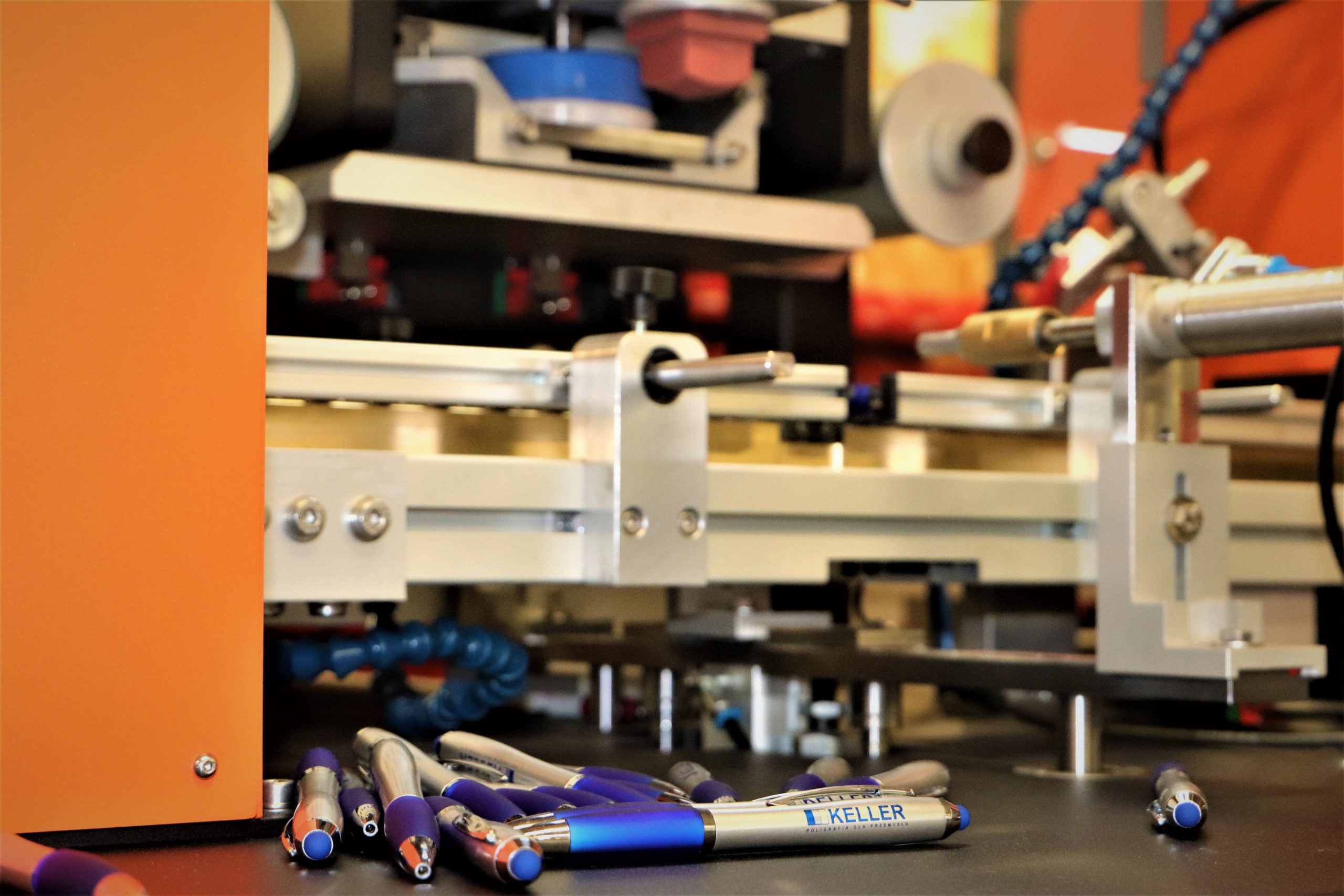

We are pleased to announce that we are starting cooperation with Lelewel printing and administration vocational school basen in Poznan, Poland. We will support the school with industrial printing and give our knowledge and passion for printing to students. The school runs professional classes that prepare students for such professions as technician of printing processes or graphics and industrial printing. Soon we will have the opportunity to conduct the first workshop at the school, in which we will introduce students to the practical aspects of screen printing, pad printing and hot stamping.